The first ocular prosthesis

In most cases the swelling of the tissue has receded after about six weeks to such an extent that a first custom made ocular prosthesis can be worn.

The first step in the process involves determining the form and size of your new ocular prosthesis by means of corresponding samples.

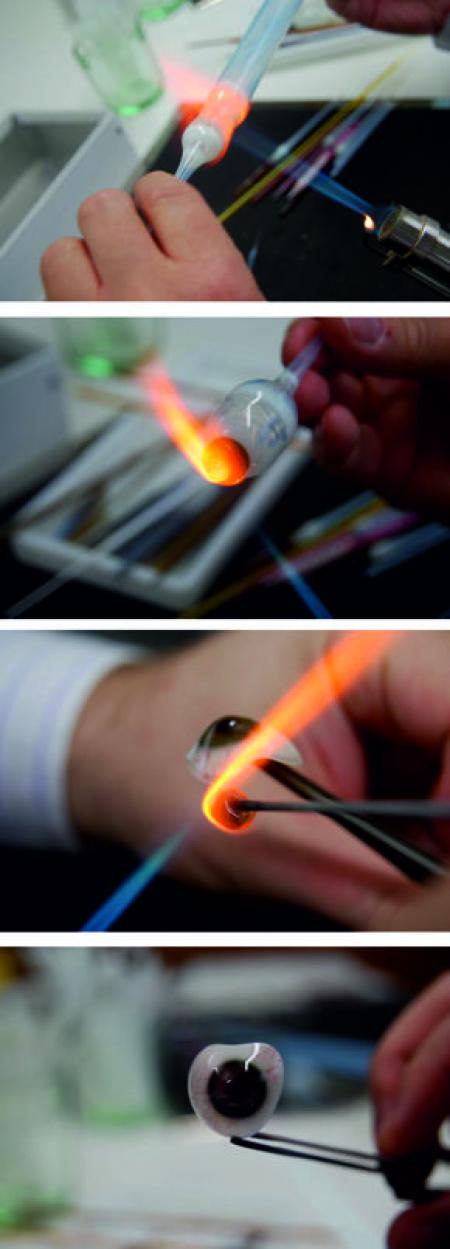

A special burner is used to first simulate the iris pattern and then the veins of the sclera. Depending on the anatomy and geometry of the orbit, the ocular prosthesis is then given its individual shape.

The fact that the processing is carried out exclusively with the flame produces a homogeneous, fire-polished surface which makes wearing the prosthesis comfortable and hygienically and allergically harmless.

Besides our headquarters in Würzburg, we are also active in a further 30 towns and cities throughout Bavaria and in the federal states of Baden-Württemberg, Hesse, Lower Saxony, Saxony and Thüringen.

We also hold consultation sessions in Copenhagen/Denmark.

At these consultation sessions we manufacture a custom ocular prosthesis in your presence which is precisely made to meet your particular needs.

All you have to do to have one made for you is arrange an appointment.